2018-01-22>

2018-01-22>

2018-01-22>

2018-01-22>

2018-01-22>

2018-01-22>

2018-01-22>

2018-01-22>

2018-01-22>

2018-01-22>

2018-01-17>

2018-01-17>

2018-01-17>

2018-01-17>

2018-01-17>

2018-01-17>

2018-01-16>

2018-01-15>

2018-01-15>

2018-01-15>

2018-01-15>

2018-01-15>

2018-01-18>

2018-01-18>

2018-01-18>

2018-01-18>

2018-01-18>

2018-01-18>

2018-01-18>

2018-01-18>

2018-01-18>

2018-01-16>

Sitemap

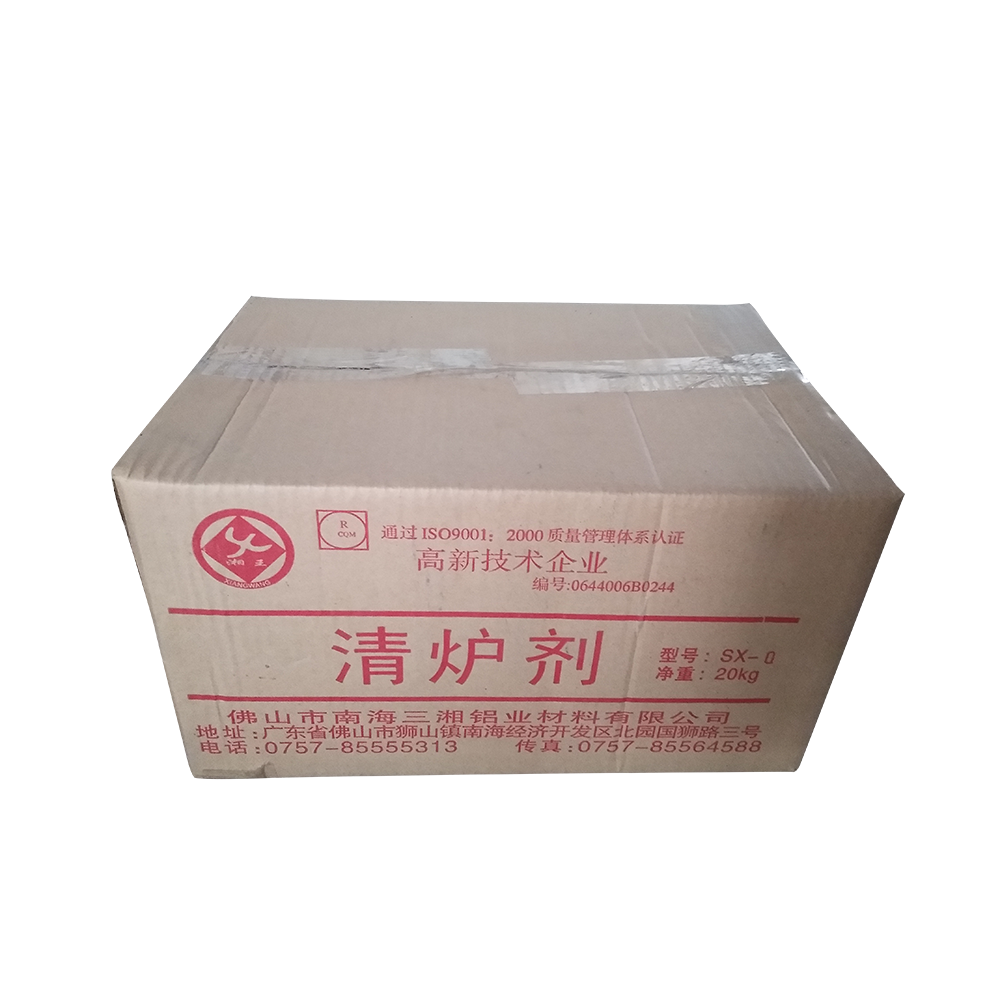

Focus on aluminum materials and surface treatment for 25 years

Professional experience factory production services testing raw materials